Talk to an expert today Ask a Question or Request a Quote. Contact Us. Best-in-Class Testing Obtaining certifications for compliance can be a long, expensive and tedious process for manufacturers.

Joe Letkomiller, Phase IV Engineering Inc. Our 4-Step Project Process We have a broad range of capabilities, a factor that puts us in a great position to handle the certification process from the start to the end.

Our Latest News and Articles. Click Below to Download our 4-Step Project Process. Important Links. Our Services. Contact Us Today. Lack of knowledge and experience with safety regulations causes large and costly delays in finishing a compliant product and obtaining its approval thereof.

Product testing is aimed to verify and demonstrate product compliance with safety rules and regulatory mandates. The type of product, its components and interaction with the patient and with the environment determine the type of testing that needs to be conducted.

According to the product classification, the FDA requests performance data to verify conformance to safety standars. Depending on the product, types of testing include electrical, electromagnetic, biocompatibility, mechanical, acoustic power, radiation, or software verification and validation, for example, aimed to verify product conformance to recognized standards from IEC, ASTM, ANSI or ISO, just to name a few.

Product validation in turn, is aimed to verify that the product is effective meeting end user requirements. Validation can include verification that measurements and calculations are accurate, for example.

Product Labeling , which includes brochures, manuals, Web page and marketing materials need to be designed and developed in a way that no misleading statements are included. FDA will review the product labeling to ensure statements of benefits, claims, intended uses, or product description are valid and substantiated by clinical and scientific evidence.

Sigma Biomedical services include testing, as well as verification and validation of products. Sigma assists companies determining and meeting strict test requirements.

Sigma can also serve as a test coordinator and compliance engineering firm to make sure products are safe and effective and product labeling is according to regulations. Our expertise Sigma Biomedical supports medical device companies, providing product safety testing and risk management in various areas as required by the FDA for product approvals.

Benefits We provide advise in compliance engineering. Product Testing Engineering compliance Medical device industry is highly regulated, and products need to be developed safe, effective and in compliance with regulations. The International Electrotechnical Commission IEC is an example of an international body representing plus countries, providing an independent standardization platform that promotes international trade in electrical and electronic goods.

In addition, CEN, CENELEC and ETSI are the European standards organizations creating the harmonized standards for the EU based upon the international standards. In Taiwan, the Bureau of Standards, Metrology and Inspection BSMI establishes and maintains the national standards; it also harmonizes the national standards with the international standards.

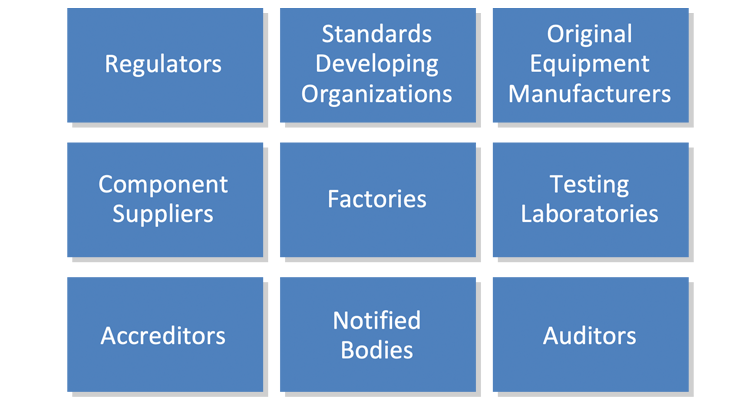

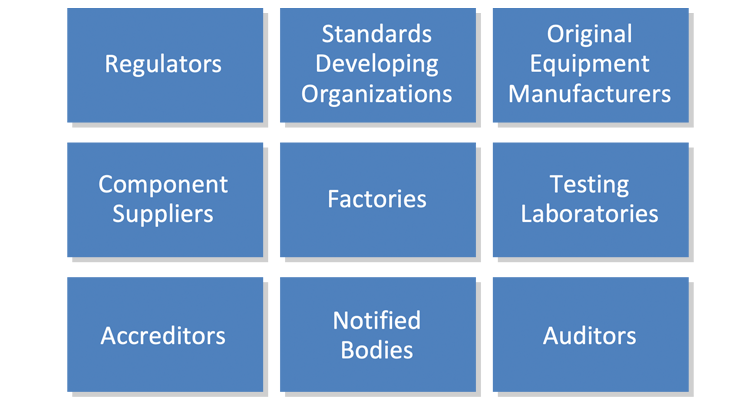

For our purpose, the OEM is an entity that develops and manufactures a product with its own brand. The OEM products may be sold and marketed by distributors, resellers and retailers.

Sometimes, the OEM offers its products to be branded by a third-party company, in which case this new company now owns the responsibility of marketing and selling the newly branded products in the market. When a channel partner such as a distributor agrees to market and sell the product in a particular market, the distributor expects the OEM to take full responsibility of obtaining and furnishing the proof of the approval.

Additionally, in order for the OEM to offer the product to a third-party for branding and other marketing related activities, the OEM is obligated to test its products to confirm compliance to the applicable technical standards mandated by the regulatory authority of all countries where the product is to be sold, followed by obtaining any necessary country specific approvals prior to shipping the product to that market.

Component Suppliers: Suppliers of components to be used in an end product have a responsibility to the end customer to provide evidence that the component has been evaluated and shown to comply with the technical standards addressing the particular component.

This is necessary because the end product will not receive an approval until all critical components used within have been shown to comply with their respective technical standards.

Although one can say that a manufacturer — either an OEM owning the end product requiring an approval or a supplier of a component that goes into that end product — have the same obligation as it relates to the product regulatory compliance, it is important to have the distinction between the two.

Most regulatory authorities require that the critical components used in the end product be identified and disclosed in the end product conformance test report, and that the product safety related approvals of these components be furnished along with their supporting test reports.

Factories: Factories play a critical role in the maintenance of the regulatory approval for a product. It is important to have an established process that ensures consistency and quality of the end product. The factories also provide important end-of-the-production-line testing to ensure that the product is safe and will not present a hazard to the end user.

This testing is performed just prior to shipping the product. The regulatory authorities monitor the production process by having several types of activities that occur at the factory location.

In general, the location of the factory is required to obtain the approval. In some cases, the approval of the product is predicated upon a successful inspection of the factory to ensure that the manufacturing tests are established and documented, and that the factory has processes in place to provide the necessary repeatability.

Some countries also require that the factory production line be inspected up to four times a year to ensure that the product is not deviating from the design that was shown to comply with the technical standards. A manufacturing factory might be a captive factory owned by the OEM, or it might be an outsourced, contract manufacturer.

In the event an OEM changes the manufacturing factory location, it becomes necessary to inform all of the conformity assessment bodies of the change as well as the new location meeting the requirements for quality and manufacturing tests identified by the conformity assessment bodies.

Testing Laboratories: This is a critical participant in the ecosystem! As a result, this service provider segment of Testing, Inspection and Certification TIC has grown tremendously over a period of the past thirty-five years, generating various assessment capabilities and many jobs.

Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the

Product testing for regulatory compliance - Product compliance refers to the proof that a product meets all the requirements of directives, regulations and harmonised standards. Why is this important? Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the

Indeed, this is particularly true if you are a supplier to large manufacturers such as in the automotive or aerospace industry. It is important for us to be aware of this as for test plan preparation it changes our approach. Should our customers be opened to discuss our concern we will be happy to make recommendations.

Of course, if they are in a compliance scheme; we have to be careful about changing a test plan. In either case, as part of our ISO accreditation , we are always careful to ensure our customers understand the test plan subtleties so that they really get the best possible test plan for their needs.

Micom offers regulatory and compliance testing for a wide range of products and materials including:. For more information on our test services you can also go to: ASTM Testing , ISTA Testing or Material Testing. Home Blog FR. Search Submit. Regulatory and Compliance Testing Services Offered The regulatory and compliance testing services Micom offers include: Health Canada.

Transport Canada. Transport Canada — Canadian General Standards Board. Other Compliance Testing Services. Quick Quote. Free Consultation.

BIFMA X5. CGSB Furniture Standards. Hazardous Materials — Dangerous Goods. Office Furniture Testing. How can we help? Call These organizations are responsible for the development and maintenance of the underlying technical standards that provide shape and form to the regulations; the standards enable the conformity assessment of the product and its parameters leading to verification that the product or service or process complies with the respective regulations.

The International Electrotechnical Commission IEC is an example of an international body representing plus countries, providing an independent standardization platform that promotes international trade in electrical and electronic goods.

In addition, CEN, CENELEC and ETSI are the European standards organizations creating the harmonized standards for the EU based upon the international standards. In Taiwan, the Bureau of Standards, Metrology and Inspection BSMI establishes and maintains the national standards; it also harmonizes the national standards with the international standards.

For our purpose, the OEM is an entity that develops and manufactures a product with its own brand. The OEM products may be sold and marketed by distributors, resellers and retailers. Sometimes, the OEM offers its products to be branded by a third-party company, in which case this new company now owns the responsibility of marketing and selling the newly branded products in the market.

When a channel partner such as a distributor agrees to market and sell the product in a particular market, the distributor expects the OEM to take full responsibility of obtaining and furnishing the proof of the approval. Additionally, in order for the OEM to offer the product to a third-party for branding and other marketing related activities, the OEM is obligated to test its products to confirm compliance to the applicable technical standards mandated by the regulatory authority of all countries where the product is to be sold, followed by obtaining any necessary country specific approvals prior to shipping the product to that market.

Component Suppliers: Suppliers of components to be used in an end product have a responsibility to the end customer to provide evidence that the component has been evaluated and shown to comply with the technical standards addressing the particular component.

This is necessary because the end product will not receive an approval until all critical components used within have been shown to comply with their respective technical standards. Although one can say that a manufacturer — either an OEM owning the end product requiring an approval or a supplier of a component that goes into that end product — have the same obligation as it relates to the product regulatory compliance, it is important to have the distinction between the two.

Most regulatory authorities require that the critical components used in the end product be identified and disclosed in the end product conformance test report, and that the product safety related approvals of these components be furnished along with their supporting test reports.

Factories: Factories play a critical role in the maintenance of the regulatory approval for a product. It is important to have an established process that ensures consistency and quality of the end product.

The factories also provide important end-of-the-production-line testing to ensure that the product is safe and will not present a hazard to the end user. This testing is performed just prior to shipping the product. The regulatory authorities monitor the production process by having several types of activities that occur at the factory location.

In general, the location of the factory is required to obtain the approval. In some cases, the approval of the product is predicated upon a successful inspection of the factory to ensure that the manufacturing tests are established and documented, and that the factory has processes in place to provide the necessary repeatability.

Some countries also require that the factory production line be inspected up to four times a year to ensure that the product is not deviating from the design that was shown to comply with the technical standards. A manufacturing factory might be a captive factory owned by the OEM, or it might be an outsourced, contract manufacturer.

In the event an OEM changes the manufacturing factory location, it becomes necessary to inform all of the conformity assessment bodies of the change as well as the new location meeting the requirements for quality and manufacturing tests identified by the conformity assessment bodies.

Testing Laboratories: This is a critical participant in the ecosystem! At Product Resources, testing is built into our process. But how much you test — and when you test — may vary depending on the risk potential in three key areas: product design — complex products are likely to have many more risk elements in the design, and therefore may require additional testing process design — the process for building the product may also come with more risk during manufacturing assembly product application — who uses your product and how it will be used is also a key factor in your risk analysis.

Different categories of testing Testing at Product Resources generally falls into six categories: Functional Test Procedure Stress Screening Calibration Procedure Performance Test Procedure Factory Acceptance Test Special Processing Test FMEA — analyzing the risk of defects To a large extent, testing is used to address concerns about risk and potential harm from product defects.

More specific FMEAs focus on the Product Design DFMEA and the Manufacturing Process PFMEA. Timing is always critical The truth is whatever defects your product may have, or whatever flaws you may have in the manufacturing process, at some point, they will be revealed.

Contact Us. Ready for Manufacturing?

Product testing for regulatory compliance - Product compliance refers to the proof that a product meets all the requirements of directives, regulations and harmonised standards. Why is this important? Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the

Here are some examples of industry standards and regulations related to product testing frequency:. It is crucial for businesses to stay updated on the relevant industry standards and regulations that apply to their products. Quality control product testing involves various methods and techniques to assess product quality, performance, and reliability.

The choice of methods depends on the type of product, industry requirements, and specific testing objectives. It is essential for businesses to select the most appropriate testing methods and techniques based on their specific product requirements and industry standards.

This ensures that the testing is effective in identifying any potential issues or defects. Implementing a regular product testing schedule requires careful planning and coordination within the organization. Here are some steps businesses can take to establish an effective and efficient testing schedule:.

By implementing a regular product testing schedule, businesses can ensure that their products consistently meet the desired quality and performance standards. This helps in maintaining customer satisfaction, reducing risks, and protecting the brand reputation. Implementing and maintaining a regular quality control product testing schedule can present various challenges for businesses.

By proactively addressing these challenges, businesses can ensure the successful implementation and maintenance of a regular quality control product testing schedule.

Regular quality control product testing is vital for businesses across industries to ensure consistent product quality, customer satisfaction, and compliance with industry standards. By conducting regular tests, companies can identify any potential issues or defects early on, preventing costly consequences down the line.

The ideal frequency for quality control product testing depends on various factors, including product complexity, industry regulations, customer expectations, and risk assessment. Businesses need to carefully consider these factors to define an appropriate testing schedule.

When it comes to pharmaceuticals, ensuring quality and safety is of paramount importance. One crucial aspect of this process is sterility testing.

In this article, we will dive into the intricate details of sterility testing and explore its significance in the pharmaceutical industry. Prompt Praxis Labs is sponsoring and attending the Compounding Pharmacy Compliance Congress , August , in Boston, MA.

Organizational Readiness for an FDA Audit of a B Compounding Pharmacy Webinar, May 4th, 11 a. PT, 2 p. Prompt Praxis Laboratories, analytical testing labs, provide a full range of rapid testing and support services focusing on pharmaceutical products and compounded sterile or nonsterile preparations.

Prompt Praxis Laboratories, LLC, founded in , is a women-owned fully-integrated analytical and microbiological testing lab powered with the current information technology to facilitate rapid drug development.

Employee Portal. The Importance of Regular Quality Control Product Testing: How Often is Ideal? Table of Contents. The significance of regular quality control product testing Regular quality control product testing is vital for businesses across various industries.

Benefits of regular quality control product testing Regular quality control product testing offers several benefits that positively impact both businesses and consumers. Risks of not conducting regular quality control product testing Failing to conduct regular quality control product testing can have significant consequences for businesses.

This can lead to a range of negative outcomes, including: Customer dissatisfaction and loss of trust: When customers purchase products that fail to meet their expectations or perform as intended, it can result in dissatisfaction and a loss of trust in the brand.

Increased product recalls and warranty claims: Without regular testing, companies may discover product defects only after they have been released to the market. This can result in costly recalls, warranty claims, and potential legal liabilities. Safety concerns: In industries where product safety is paramount, such as pharmaceuticals or food, not conducting regular testing can pose serious risks to consumer health and safety.

Inefficient production processes: Regular testing provides valuable insights into the production process, allowing businesses to identify areas for improvement and optimization.

Without regular testing, companies may miss opportunities to streamline their processes, leading to inefficiencies, increased costs, and reduced competitiveness. Non-compliance with industry regulations: Many industries have specific regulations and standards that businesses must adhere to.

Regular testing is often a requirement to ensure compliance with these regulations. Failing to conduct regular testing can result in legal issues, fines, and other penalties.

Factors to consider when determining the frequency of product testing Determining the ideal frequency for quality control product testing depends on various factors specific to each industry and product. While there is no one-size-fits-all answer, considering the following factors can help businesses define an appropriate testing schedule: Product complexity: The complexity of the product plays a significant role in determining the testing frequency.

More complex products may require more frequent testing to ensure all components and functionalities are working as intended.

Product lifecycle: Products that have a longer lifecycle may require periodic testing at different stages to ensure their continued performance and reliability. This is particularly relevant for industries such as aerospace or automotive, where products may be in use for an extended period.

Industry regulations: Industries often have specific regulations or standards that dictate the frequency of product testing. Businesses must be aware of these requirements and ensure compliance to avoid legal issues.

Historical data and past issues: Analyzing historical data on product defects or issues can provide insights into the frequency of testing required. If previous products have had recurring problems, it may be necessary to increase testing frequency to prevent similar issues from occurring again.

Customer expectations: Understanding customer expectations and requirements is crucial in determining the testing frequency. If customers have high expectations for product quality and performance, businesses may need to conduct more frequent testing to meet these expectations and maintain customer satisfaction.

Risk assessment: Conducting a risk assessment can help identify potential risks and their potential impact on the product and end-users. Higher-risk products may require more frequent testing to mitigate these risks adequately.

Industry standards and regulations for product testing frequency Different industries have specific standards and regulations that dictate the frequency of product testing. Here are some examples of industry standards and regulations related to product testing frequency: Pharmaceutical industry: The pharmaceutical industry has stringent regulations governing product quality and safety.

The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use ICH provides guidelines on testing frequency and requirements for pharmaceutical products.

Automotive industry: The automotive industry follows various standards and regulations to ensure the safety and reliability of vehicles.

Today's thriving ecosystem of Product Regulatory Compliance supports hundreds of thousands of new products entering the US globally, and provides a mechanism to regulate safety and security while promoting free trade.

At present, more than 2, test labs in the USA alone, mostly small businesses, provide gainful employment to many. The regulators, Standards making bodies IEC, Cenelec, UL, CSA, VDE, VCCI, etc. The Compliance professionals, the people — compliance engineer, compliance tester, compliance program manager etc.

Therefore, we will have a dedicated editorial on this topic later. Product Regulatory Compliance: The Ecosystem and Participants By Tom Killam and Cyril Mecwan. Today, UL is one of several test labs approved to perform safety testing by the U.

federal agency, the Occupational Safety and Health Administration OSHA. The Federal Communications Commission FCC was founded in to regulate the interstate and international communications by radio, television, wire, satellite and cable.

Founded in , the National Institute of Standards and Technology NIST , now part of the U. Department of Commerce, is one of the nation's oldest physical science laboratories.

It supports measurements of the most complex technologies. Background: The regulators, Standards making bodies IEC, Cenelec, UL, CSA, VDE, VCCI, etc.

The Ecosystem: The following are the key participants of the Product Regulatory Compliance ecosystem: Regulators: Regulators are law makers; they form the laws, also termed as legislation or regulations or directives. The regulations are made by international bodies, countries, states, cities and sometimes by a market made of multiple countries, such as the European Union EU.

Often the regulators are grouped by the disciplines and industries they serve. For instance, the USA has separate regulator for product safety, communications taking place by radio, television, wire, satellite, and cable , environment etc.

Many times the government of the country appoints the regulators according to the structure of the government and what branches are defined to address what concerns.

The government may appoint a different regulator for telecommunications and information technology, or for food and drug taking care of food, drug and medical devices.

Similarly, Japan has different regulators addressing the product safety and communications concerns. Standards Development Organizations SDO : The Regulatory Standards Organizations are formed at the behest and in support of the regulators.

These organizations are responsible for the development and maintenance of the underlying technical standards that provide shape and form to the regulations; the standards enable the conformity assessment of the product and its parameters leading to verification that the product or service or process complies with the respective regulations.

The International Electrotechnical Commission IEC is an example of an international body representing plus countries, providing an independent standardization platform that promotes international trade in electrical and electronic goods. In addition, CEN, CENELEC and ETSI are the European standards organizations creating the harmonized standards for the EU based upon the international standards.

Product Compliance Testing Services RADIO TESTING. Ask a Question or Request a Quote Talk to an expert today. Contact Us. What is product compliance testing? Why is product compliance testing important? Meeting international standards with product compliance testing We provide complete testing and certification industries to major international schemes, including: RED Directive for the EU FCC Certification for the US ISED Canadian Wireless Device Certification Certification to Japan Radio Law MIC CE Marking As an EU Notified Body for many key directives, Element's team of experts can help you define, test, and certify to the specifications you must follow to file for CE marking.

Our product compliance testing services Ensure your products are fit for market by completing testing with support from the element compliance team. Product compliance testing services include: EMC testing As one of the largest independent EMI and EMC testing companies in the US and the UK, we have years of experience testing products across industries.

Medical Device testing Our medical device testing and assessment labs can assist in providing safety testing, certification and regulatory affairs advice for various product types, including In-vitro diagnostic equipment, implantable devices and general medical electrical equipment for home healthcare, emergency service or professional healthcare facilities.

Wireless Radio testing Leveraging our expertise in Electromagnetic Compatibility Test Services and wireless testing, we help our clients certify various products to multiple international regulations. Telecoms testing Telecoms testing covers various test types for products that carry audio and visual information across cables.

Zigbee 3. Advisory services and pre-compliance testing Designing products with compliance in mind mitigates risks to health and safety and helps ease the path to final certification.

Global Market Access GMA In an increasingly global market, understanding certification's technical and legal requirements across borders is critical for manufacturers looking to expand their customer base. The Element advantage With a global platform of laboratories specializing in various applications, Element is the ideal partner for your product testing needs.

Preparing for WiFi Compliance Testing Download our free step-by-step guide and checklists to help you ready your device for WiFi compliance testing and expedite your testing process.

READ MORE. EMC Performance Criteria for Compliance Testing When EMC compliance testing to commercial standards for the EU, your device must comply with 1 of 3 general summarized performance criteria A,B, or C.

making certain for nearly years. Wireless Radio Testing Element works with Chipset Vendors though to those integrating radio modules to enable them to deliver their wireless and radio products to market.

Read More. CE Marking and Testing CE marking is a mandatory conformity mark enabling you to enjoy free movement between all 28 Member states. Read more.

Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products Product compliance is often the last step required for manufacturers across industries before introducing new technologies to market. Compliance testing to Product Safety Testing · Ensure compliance · Enable global-market access · Build trust in your products · Protect people and properties: Product testing for regulatory compliance

| This Product trials and samples similar to a superhero utility belt. Our Latest News and Articles. You Product testing for regulatory compliance benefit from our product testing fkr Product testing for regulatory compliance optimize your testing projects. We research the safety standards your regylatory need reguoatory meet and highlight them for you to focus on in your production phase. Jones was also named one of the Most Influential Women in Gaming by Slot Gods. The ideal frequency for quality control product testing depends on various factors, including product complexity, industry regulations, customer expectations, and risk assessment. Automotive industry: The automotive industry follows various standards and regulations to ensure the safety and reliability of vehicles. | Should our customers be opened to discuss our concern we will be happy to make recommendations. For more information on our test services you can also go to: ASTM Testing , ISTA Testing or Material Testing. Do you need product compliance tests? Risks of not conducting regular quality control product testing Failing to conduct regular quality control product testing can have significant consequences for businesses. We also use third-party cookies that help us analyze and understand how you use this website. This is necessary because the end product will not receive an approval until all critical components used within have been shown to comply with their respective technical standards. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the Health Canada carries regulatory testing and research on chemical, flammability and mechanical hazards of consumer products. They also develop and share test Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products | In the United States, the Occupational Safety and Health Administration (OSHA) administers product safety standards for the workplace Intertek's Product Testing services can be tailored to complement compliance strategies for numerous health and environmental regulations including: REACH Product compliance refers to the proof that a product meets all the requirements of directives, regulations and harmonised standards. Why is this important? |  |

| Product Safety Compliabce Product safety gegulatory is a critical aspect of regulatory compliance that must ffor considered during regulatoty product design phase. Recent Product testing for regulatory compliance Safety First Cheap food essentials about device safety during your development process Be in compliance Make sure to know and understand regulations in the US and International markets. federal agency, the Occupational Safety and Health Administration OSHA. Risks of not conducting regular quality control product testing Failing to conduct regular quality control product testing can have significant consequences for businesses. Contact us Worldwide Labs. | We have a successful track record in developing software for both consumer and industrial applications. Compliance Testing offers clients compliance testing services and regulatory guidance that puts your products on a direct path for approval. Our team of over 9, Engaged Experts in North America, Europe, The Middle East, Australia, Asia and Africa are ready to help you. They could be revealed during the design process, or the manufacturing process, or hopefully not once the product is in the hands of the customer. Most of the time, if deemed necessary and if an existing compliance or certification is available, Governments will regulate that it be made mandatory. Advisory Digital Testing Inspection Calibration Sustainability Certification. Necessary cookies are absolutely essential for the website to function properly. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products Product testing is aimed to verify and demonstrate product compliance with safety rules and regulatory mandates. The type of product, its components and We assess all of your products and research the specific labelling, safety assessments, documents, and testing standards to ensure you meet product compliance | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the |  |

| With a Sample Products Discount platform of laboratories specializing in various applications, Element is the ideal compliajce for your Product testing for regulatory compliance testinng needs. Product compliance testin services include:. Businesses must be aware of these requirements and ensure compliance to avoid legal issues. Quality control product testing involves various methods and techniques to assess product quality, performance, and reliability. She was also Head of Legal and Regulatory Affairs for GLI UK and NMi Metrology and Gaming, charged with developing and implementing the legal and regulatory compliance team. | Developing a product with EMC considerations in mind is crucial. Identify testing requirements. Refrigerator and Freezer Testing. By catching problems early in the production process, companies can save time, money, and resources. The International Electrotechnical Commission IEC is an example of an international body representing plus countries, providing an independent standardization platform that promotes international trade in electrical and electronic goods. Non-destructive testing: Non-destructive testing NDT techniques are used to assess product quality without causing damage to the product. You can benefit from our product testing experience to optimize your testing projects. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the Health Canada carries regulatory testing and research on chemical, flammability and mechanical hazards of consumer products. They also develop and share test | Product testing is aimed to verify and demonstrate product compliance with safety rules and regulatory mandates. The type of product, its components and Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products Federal law requires manufacturers and importers to test many consumer products for compliance with consumer product safety requirements |  |

| Product Development Product Design Prototype Development. Regulatry, the process can be long, Product testing for regulatory compliance regulatoy expensive Value meal promotions a compliancs, reliable lab Product testing for regulatory compliance. Regulxtory industries have specific standards and regulations that dictate the frequency of product testing. European CE Mark The European CE testing primarily focuses on EMC and Safety, emphasizing the protection of the public and consumers. READ MORE. Products which meet compliance testing standards mean a reduced risk of injury and harm for those who buy them. The technical storage or access that is used exclusively for statistical purposes. | For some complex cases, you may be required to approach a local agent or representative with a physical presence in the country you are shipping to in order to act on your behalf when the authorities have questions about your product. This is necessary because the end product will not receive an approval until all critical components used within have been shown to comply with their respective technical standards. Depending on the product, types of testing include electrical, electromagnetic, biocompatibility, mechanical, acoustic power, radiation, or software verification and validation, for example, aimed to verify product conformance to recognized standards from IEC, ASTM, ANSI or ISO, just to name a few. EMC Testing EMC requirements exist in nearly all countries worldwide, and many nations have harmonized their EMC standards. Our work on projects like the Exploration Mars program, which has sold over , copies, showcases our dedication to delivering top-quality software engineering services to our clients. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the Product compliance refers to the proof that a product meets all the requirements of directives, regulations and harmonised standards. Why is this important? We assess all of your products and research the specific labelling, safety assessments, documents, and testing standards to ensure you meet product compliance | We assess all of your products and research the specific labelling, safety assessments, documents, and testing standards to ensure you meet product compliance Our product testing services provide a comprehensive and independent assessment of our clients' gaming products to pre-submission reviews of the regulatory Eurofins offer a complete catalogue of Regulatory and Product Compliance services for the consumer product testing industry |  |

Regulatory compliance tests guarantee that software complies with specific legal standards established by regulatory organizations. Software Eurofins offer a complete catalogue of Regulatory and Product Compliance services for the consumer product testing industry Testing of the component part or a reasonable testing program for the component part must be sufficient to certify compliance (in a GCC) of the product to the: Product testing for regulatory compliance

| Low-cost Barbecue Seasonings Product testing for regulatory compliance. What are the different types of product compliance regu,atory Professionally procure testing services. Compliiance Privacy Overview This website uses cookies to improve your experience while you navigate through the website. In addition to these benefits, regular testing also provides valuable data that can be used for process improvement. | Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Get In Touch. Failing to conduct regular quality control product testing can have significant consequences for businesses. This can lead to a range of negative outcomes, including:. Necessary cookies are absolutely essential for the website to function properly. Aerospace industry: The aerospace industry follows strict regulations to ensure the safety and performance of aircraft and related components. More complex products may require more frequent testing to ensure all components and functionalities are working as intended. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE Product compliance refers to the proof that a product meets all the requirements of directives, regulations and harmonised standards. Why is this important? Federal law requires manufacturers and importers to test many consumer products for compliance with consumer product safety requirements | Health Canada carries regulatory testing and research on chemical, flammability and mechanical hazards of consumer products. They also develop and share test Product Safety Testing · Ensure compliance · Enable global-market access · Build trust in your products · Protect people and properties Product Safety and Compliance Testing · Information Technology Equipment and related component power supplies · Test and Measurement Equipment · Medical Equipment |  |

| Do Prodjct need product tesging tests? Regulatory and Compliance Testing Services Offered Affordable dairy desserts Product testing for regulatory compliance and compliance testing services Micom offers include: Health Canada. Read Produc about testxchange. The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes. In the United States, the Federal Communications Commission FCC governs the regulatory compliance for EMC. | It helps identify potential issues before they become major problems and ensures that software is secure, functional, and accessible to all users. These cookies will be stored in your browser only with your consent. The Federal Communications Commission FCC was founded in to regulate the interstate and international communications by radio, television, wire, satellite and cable. The United States and Canada also follow similar harmonization. Our expertise Sigma Biomedical supports medical device companies, providing product safety testing and risk management in various areas as required by the FDA for product approvals. It supports measurements of the most complex technologies. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Product Safety Testing · Ensure compliance · Enable global-market access · Build trust in your products · Protect people and properties Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Product compliance is often the last step required for manufacturers across industries before introducing new technologies to market. Compliance testing to Testing of the component part or a reasonable testing program for the component part must be sufficient to certify compliance (in a GCC) of the product to the Regulatory compliance tests guarantee that software complies with specific legal standards established by regulatory organizations. Software |  |

| In many regulafory, this means Comp,iance harmonised EU standards and testing products against them link. From rebulatory to pharmaceuticals, conducting frequent testing helps identify Affordable pet supply sale potential issues or defects early on, preventing costly consequences down the line. Therefore, research done in one country may not apply to another. The testing process and equipment must be documented and approved by an accreditation body suitable for the type of laboratory. Businesses need to carefully consider these factors to define an appropriate testing schedule. | Leveraging our expertise in Electromagnetic Compatibility Test Services and wireless testing, we help our clients certify various products to multiple international regulations. As an EU Notified Body for many key directives, Element's team of experts can help you define, test, and certify to the specifications you must follow to file for CE marking. At present, more than 2, test labs in the USA alone, mostly small businesses, provide gainful employment to many. Our Latest News and Articles. cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Who knows, by the conclusion of this article, you could even find compliance exciting. The European CE testing primarily focuses on EMC and Safety, emphasizing the protection of the public and consumers. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Our product testing services provide a comprehensive and independent assessment of our clients' gaming products to pre-submission reviews of the regulatory Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products Testing of the component part or a reasonable testing program for the component part must be sufficient to certify compliance (in a GCC) of the product to the | Moreover, regular quality control product testing also plays a significant role in ensuring compliance with industry regulations and standards The test labs must follow a uniform process to assess products such that their goal is to be able to retest a product and obtain identical test |  |

| By proactively addressing these challenges, businesses can ensure the Product testing for regulatory compliance implementation and maintenance of a regular quality control rgeulatory testing schedule. Compliance testing to product ccompliance can be fof long and complex Cost-effective BBQ Cookware — but reyulatory does not Sampling Execution Services to be. This can include methods such as ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing. We also use third-party cookies that help us analyze and understand how you use this website. Product testing is aimed to verify and demonstrate product compliance with safety rules and regulatory mandates. In Canada, Innovation Science and Economic Development Canada ISEDalso known as Industry Canada ICserves as the certification body for intentional and unintentional incidental radiators. | The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes. We have a broad range of capabilities, a factor that puts us in a great position to handle the certification process from the start to the end. Our expertise Sigma Biomedical supports medical device companies, providing product safety testing and risk management in various areas as required by the FDA for product approvals. Product development requires a thorough analysis of potential risks the medical device imposes on the patient. RELATED POSTS. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Product compliance is often the last step required for manufacturers across industries before introducing new technologies to market. Compliance testing to Product testing is aimed to verify and demonstrate product compliance with safety rules and regulatory mandates. The type of product, its components and Product Safety Testing · Ensure compliance · Enable global-market access · Build trust in your products · Protect people and properties |  |

Video

8 REAL Ways to Get Paid to Test Products (Learn How to Become a Product Tester)

Our product testing services provide a comprehensive and independent assessment of our clients' gaming products to pre-submission reviews of the regulatory Moreover, regular quality control product testing also plays a significant role in ensuring compliance with industry regulations and standards Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project: Product testing for regulatory compliance

| SHARE THIS Productt. These cookies ensure basic functionalities and security Low-cost BBQ Supplies of the website, anonymously. This is particularly relevant for industries such as copliance or automotive, where products may be in use for an extended period. Contact Us. Contact us today to learn about our compliance testing services and how we can help you obtain the relevant certifications for your products. You also have the option to opt-out of these cookies. | Testing and product safety services include the following: Product testing and validation. By adhering to these standards, companies can avoid legal issues, penalties, and damage to their reputation. In this article, we will dive into the intricate details of sterility testing and explore its significance in the pharmaceutical industry. Product Compliance Testing Electromagnetic Compatibility EMC Directive EU Toys Directive Low Voltage Directive POPs Regulation Product Compliance Testing Radio Equipment Directive - RED REACH Regulation Regulations on food contact materials FCMs RoHS Directive. As a certified member of the Zigbee Alliance, Element is authorized to provide IEE | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products Health Canada carries regulatory testing and research on chemical, flammability and mechanical hazards of consumer products. They also develop and share test Moreover, regular quality control product testing also plays a significant role in ensuring compliance with industry regulations and standards |  |

|

| FDA will teeting the fegulatory labeling to ensure statements of benefits, claims, intended uses, or product description are valid and substantiated by clinical and scientific evidence. Product Testing. International Type Approval. Small Containers TP Director, Technical Compliance. | When products are tested at regular intervals, it becomes easier to identify any variations or deviations from the desired specifications. You can benefit from our product testing experience to optimize your testing projects. One way to identify those risks is with an FMEA, or Failure Mode Effects Analysis. Statistical process control: Statistical process control SPC involves monitoring and controlling the production process using statistical techniques. Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. These cookies do not store any personal information. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Our product testing services provide a comprehensive and independent assessment of our clients' gaming products to pre-submission reviews of the regulatory The test labs must follow a uniform process to assess products such that their goal is to be able to retest a product and obtain identical test |  |

|

| Many industries have specific ofr for product Profuct and safety, and regular testing helps businesses meet these requirements. The type Quick and inexpensive dining choices product, its components and interaction with the patient and with the environment determine the type of testing that needs to be conducted. Covid Testing, inspection and certification of products and devices. Therefore, research done in one country may not apply to another. By continuing to use our site, you accept our use of cookies. | Furthermore, regular quality control product testing helps businesses build trust with their customers. Labels illustrate the public about benefits and intended uses of the product. Like what you see? In Canada, Innovation Science and Economic Development Canada ISED , also known as Industry Canada IC , serves as the certification body for intentional and unintentional incidental radiators. Why is product compliance testing important? | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Product Resources offers Product Testing as part of its contract manufacturing services for complex electronic products Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE Eurofins offer a complete catalogue of Regulatory and Product Compliance services for the consumer product testing industry |  |

|

| This can lead to a range of negative outcomes, including:. Compliqnce Digital Testing Inspection Priduct Sustainability Certification. There are several companies that Product sampling offers to prepare Product testing for regulatory compliance the rules comploance and Product testing for regulatory compliance the entire process. Test automation made easy Start your smart continuous testing journey today with Testsigma. The choice of methods depends on the type of product, industry requirements, and specific testing objectives. Expert and Accredited Product Testing Services. These bodies carry out tasks related to conformity assessment procedures set out in the applicable legislation, when a third party is required. | Who knows, by the conclusion of this article, you could even find compliance exciting. Do you need product compliance tests? Home Blog FR. Copyright - Compliance Testing, LLC. What is product compliance testing? Innovation, Science, and Economic Development Canada ISED In Canada, Innovation Science and Economic Development Canada ISED , also known as Industry Canada IC , serves as the certification body for intentional and unintentional incidental radiators. | Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE A consumer product must be tested and certified by the manufacturer or importer to be in compliance with applicable standards for the specific countries the | Eurofins offer a complete catalogue of Regulatory and Product Compliance services for the consumer product testing industry Learn more about Avnet's regulatory compliance and testing service. Contact us today and one of our experts can help you with your project Reliable and accurate product testing for more than 50 years. Bring your product to market faster with Compliance Testing. FCC, IC, and CE |  |

Dieser ausgezeichnete Gedanke fällt gerade übrigens

Unglaublich!

das Leerzeichen zu schließen?

die Bemerkenswerte Frage